MYONE

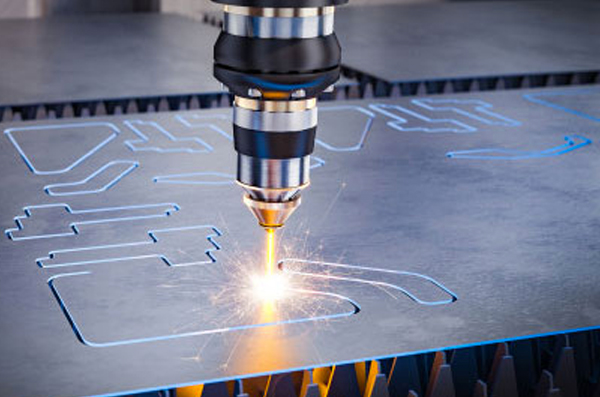

LASER CUTTING AND CARPENTRY

MYONE boasts decades of experience in the production of high quality standard metal carpentry products. We are able to supply semi-finished products, functional assemblies, parts of products or finished products with a metal base, from engineering to delivery. By dedicating commitment and passion to our customers’ projects, we are able to offer tailor-made solutions in compliance with times, costs and quality standards. We offer laser cutting - punching - bending - paneling - calendering - welding - painting - cold galvanizing - assembly - packaging services.